Add to Cart

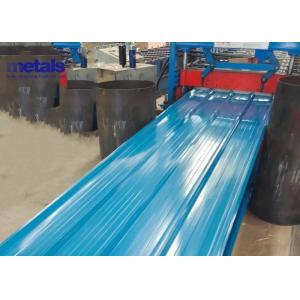

Prepainted GI Steel Sheet / PPGI / PPGL Color Coated Galvanized Corrugated Metal Roofing Sheet

PPGI is short for pre-painted galvanized steel, while PPGL is short for pre-painted galvalume steel. As the name suggests, PPGI uses galvanized sheets (with a layer of zinc coating) as base metal. While PPGL is with galvalume sheet as substrate, which is coated with 55% aluminum, 43.3% zinc, and 1.6% silicon. This is the main difference between PPGI and PPGL, which will further influence their features and applications.

With the same coating thickness, Al-Zn coating is lighter than zinc coating. It is because the specific weight of aluminum is lower than that of zinc. That is to say, with the same weight, Al-Zn coating can cover 3% more space than the GI sheet.

| Product Name | Prepainted GI Steel Sheet / PPGI / PPGL Color Coated Galvanized Corrugated Metal Roofing Sheet | ||

| Application: | Construction & Industrial | Thickness: | 0.2-3mm |

| Standard: | ASTM | Width: | 762-1000mm |

| Certificate: | BIS, JIS, ISO9001 | Grade: | Synthetic resin,PVC ASA |

| Coating: | Z30-Z40 | Tolerance: | ±1% |

| Processing Service: | Welding, Punching, Cutting, Bending, Decoiling | Color | PANTONE |

| Hardness: | Mid Hard | Delivery Time: | 15-21 days |

| Product Name: | Galvanized Corrugated Sheet/Galvalume Corrugated Sheet | Type: | Steel Plate, Color Coated Steel Sheet |

| Surface: | Galvanized Coated | Packing: | Standard Seaworthy Packing |

| Color: | Customized Color | Sample: | Provided |

| ZINC coating: | AZ 30g/㎡-275g/㎡ | Shape: | Wave Plate |

| PAYMENT: | T/T30% Deposit+70% Advance | Usage: | Roof Constrution Materials |

Color Coated Galvanized Corrugated Metal Roofing Sheet Advantage:

Corrugated prepainted gi steel roofing sheet has the characteristics of light weight, high strength, rich color. convenient and fast construction,earthquake resistance, fire prevention,rain protection.long life and maintenance-free etc., and has been widely popularized and applied.

(1)Beautiful and novel shape, rich colors, strong decoration and flexible combination, which can express different architectural styles;

(2) Light dead weight, high strength, good skin stiffness, and good seismic performance of waterproof agent.

(3) High quality of factory products;

(4) Convenient construction and installation, reducing the workload of installation and transportation and shortening the construction period,

(5) The poled steel sheet is an environment-friendly building material, which can be recycled.The popularization and application of profiled steel sheet conforms to the policy of sustainable development of national economy;

(6) Monomer materials are expensive and have poor durability compared with concrete or masonry enclosure materials

Production Process of PPGI Coil and PPGL Coil

The most commonly used method is a double-side and twice-coating process. It means the back and topsides will be painted twice. Let’s review step by step.

1. Pre-treatment

GL coils and GI coils are uncoiled and welded first. Then go through the inlet looper to be cleaned and pre-treated continuously (such as degreasing). After that, a layer of chemical conversion coating is formed on the surface.

2. Painting Process

The back and top sides of the steel coil will be painted and dried. Generally, the top coating will be thicker, say 10-35um. The thickness of the coating can be customized according to your requirements.

3. Cool down the coated steel coil.